Aluminium Investment Casting

Lestercast is a leading global manufacturer of Aluminium Investment castings. We have been supplying customers across all industries with the highest quality precision castings for over 50 years. We are passionate about investment casting and believe that this highly efficient manufacturing process can reduce customer costs.

We are proud to be the number one choice of many OEMs and Tier 2 suppliers in the Motorsport industry. In recent years we have seen a huge increase in demand for Aluminium manufactured parts from our foundry due to the emission/performance requirements within the Automotive and Motorsport sector. Aluminium is increasingly popular in the automotive, motorsport and aerospace industries due to it’s low density, corrosion resistance and high thermal conductivity. Its high strength to weight ratio, with Aluminium 40% lighter than steel, delivers significant enhancements to automotive & aerospace performance, whilst reducing emissions and fuel economy.

Aluminium investment casting is popular because it is extremely versatile in use and it’s base-properties. It’s relatively low-weight in comparison with other metals enabling it’s use across a wide cross-section of industries and sectors where weight may be integral to it’s finished usage. Aluminium itself is also well-known for it’s corrosion-resistance properties allowing it to be used in circumstances where this is a key factor in its end use. In it’s basic form, Aluminium is highly recyclable, so in addition to being light for transportation and reusable without losing its fundamental properties; sits well with its environmental and sustainability factors.

At Lestercast, we have been manufacturing precision Aluminium investment castings from our modern foundry for over 50 years. In this time we have developed our own special techniques for producing the highest quality Aluminium Investment Castings efficiently.

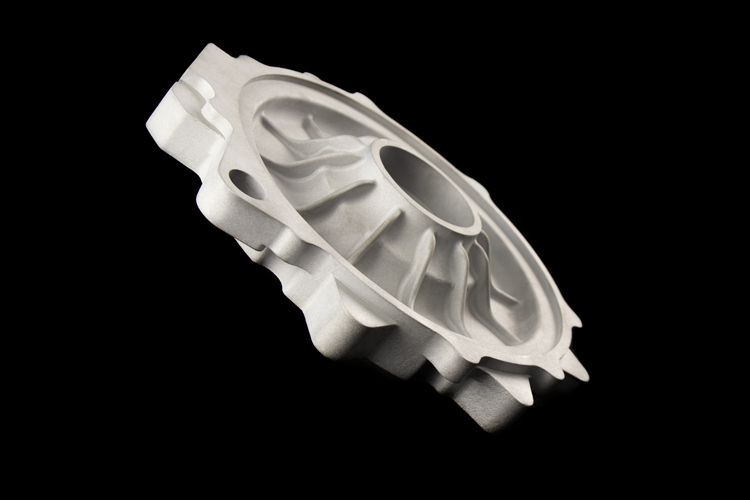

Aluminium Rapid Prototyping

At Lestercast we offer an Aluminium Rapid Prototyping service which consists of 3d printing the wax patterns, elimination the need for tooling. This can be very beneficial during development stages, for customers wishing to produce lower volumes and for manufacturing very complex parts. If you would like to read more about our aluminium rapid prototyping options please visit our rapid prototyping page.